The AEON Laser REDLINE Series Is Now In New Zealand!!

Why Redline?

The AEON Redline Series laser is designed to maximize profits with its primary focus on increasing efficiency, versatility and ease of use, while simultaneously reducing downtime and overall maintenance.

REDLINE

Noun. Red·line ‘RED-LĪN. : A recommended safety limit: The fastest, farthest, or highest point of degree considered safe and reliable.

Are you interested in the Redline series lasers?

Chat to one of our friendly, NZ based team today.

EFFICIENT

Up to 8G Acceleration

Full AC Servo Motors make acceleration nearly instant at 8G of force with top speeds of 4,200 mm/sec on all RF models.

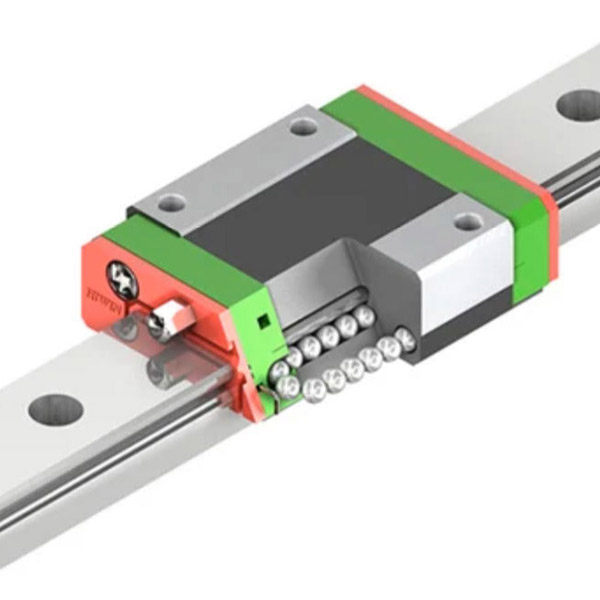

Precise & Smooth

Linear guide rails with ball bearings offer greater precision and smoother motion, which improves print quality and longevity.

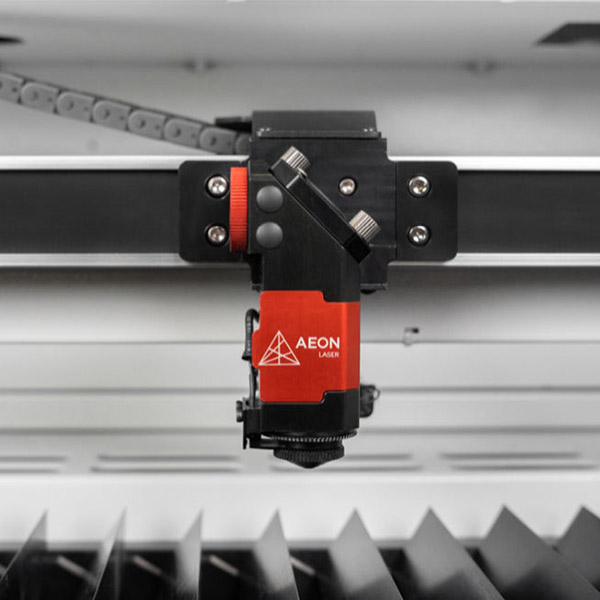

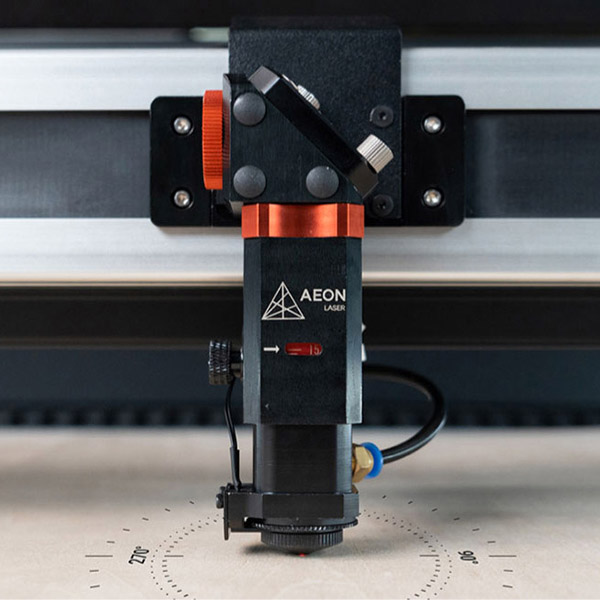

Lightweight Laser Head

A lightweight laser head contributes to less over-scanning and an overall reduction in vibration.

ROBUST & VERSATILE LASERS

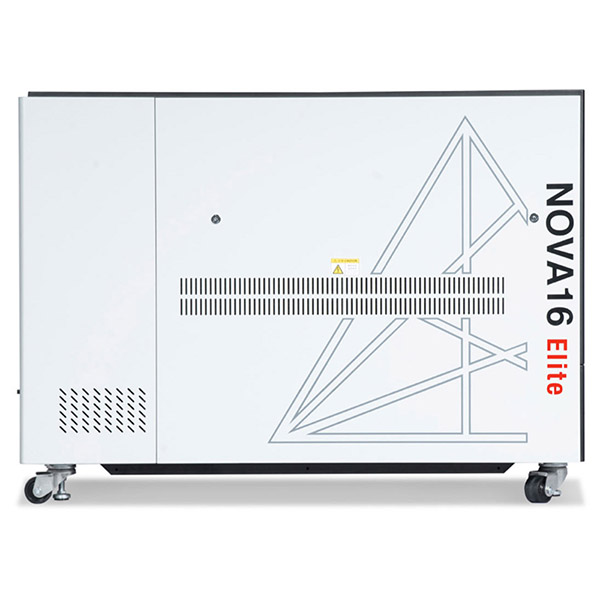

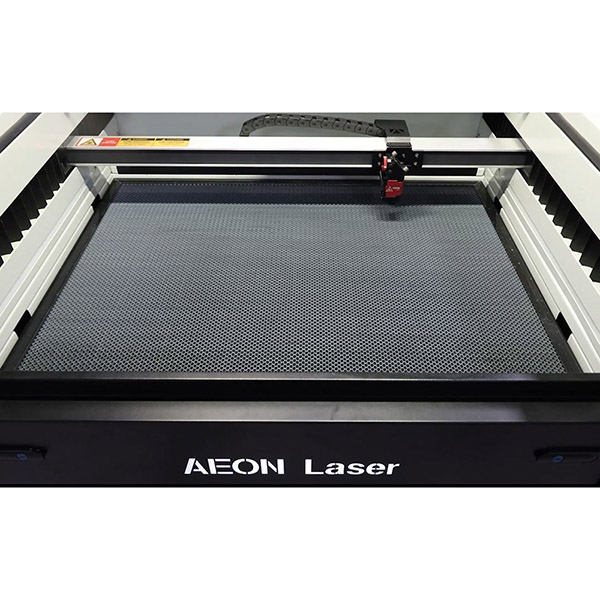

Robust Unibody

Most lasers employ a unibody structure where the components are bolted to a thin outer shell. However, if you have the need for speed, it’s of utmost importance to make the frame as rigid as possible to stop the machine from flexing. The Redline series frame is so robust, you can even remove the entire side panel for greater accessibility when troubleshooting.

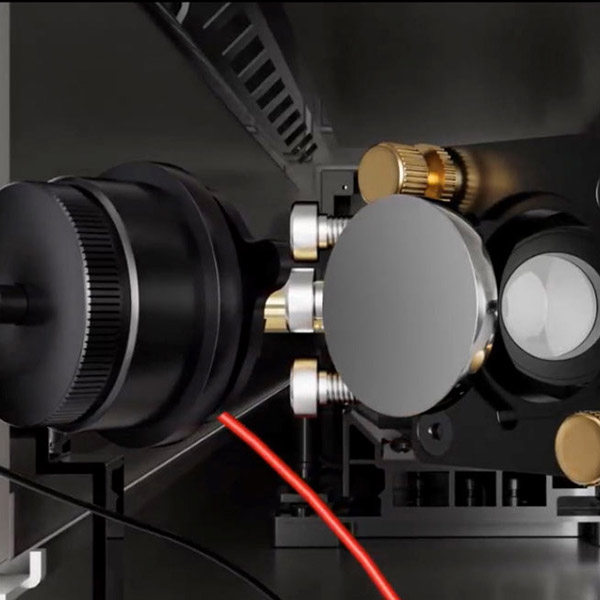

Modular Tube Docking Station

Say goodbye to painstaking tube replacements. This innovative approach allows for swapping of tubes in and out of your AEON laser, without having to renegotiate the beam path. This means it is now feasible to keep a spare tube on the shelf or quickly swap between higher or lower wattage tubes as needed. Furthermore, the stage is now set to allow switching between various wavelengths on all models, such as 1064nm Fiber lasers. This opens up a whole new world of possibilities by vastly increasing the range of materials one can process while delivering results of the utmost quality.

COMPACT

All-In-One Design MIRA

The MIRA series now joins the NOVAs with its Super Clean Pack design. Not only are the linear rails and bearing blocks enclosed, but protective curtains on the left and right side rails now prevent unwanted particles from spreading beyond your work area. Centrifugal fans have been replaced by quieter and easier to clean inline fans, and the design team was finally able to include an infinite front-to-back passthrough in all MIRA models!

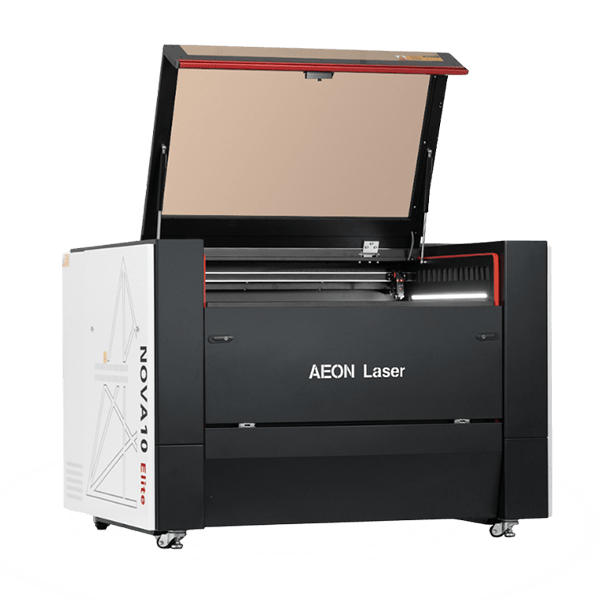

All-In-One Design NOVA

The NOVA and SuperNOVA have been redesigned with the control cabinet in the rear and a dedicated compartment for the optional RF laser tube. The DC Glass laser tube returns to the top position and all models come equipped with a built in air compressor and air tank beneath the bed.

COMPREHENSIVE

High-Resolution Camera

All AEON lasers are now equipped with built-in high-resolution cameras for precise positioning and monitoring.

Integrated Autofocus

Say goodbye to collisions and gouged material. The AEON Redline Series has a newly designed laser head with integrated autofocus.

Bullseye Leveling Gauge

Ensuring your laser is level can now be done at a glance. Both MIRAs and NOVAs are fitted with Bullseye Leveling Gauges.

BRILLIANT

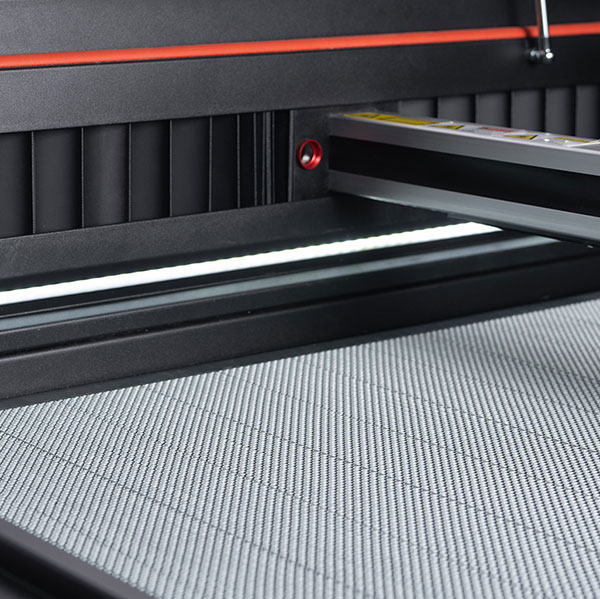

Brighter Work Area

The already well-lit work area just got brighter with the addition of 2 more LED lights on the underside of the MIRA lid, just behind the handle. When the lid is opened, the 2 interior LEDs turn off and the overhead lights turn on to illuminate your work area, while loading material and using the camera. There is even a dimmer knob on the side of the machine for setting the mood just right.

Status Light

AEON is renowned for its stylish and sleek appearance. The AEON Laser logo on the front access door panel is now backlit and doubles as a functional Status Light, illuminating white when in standby, red when an error is encountered, and green while in operation, adding both form and function to an already stunning design.

TOOLLESS

Tube Replacements

The modular laser tube docking station allows for instant tube replacements free from tools, all while maintaining the beam path.

Mirrors

All mirrors are now easily accessible and can be cleaned or replaced without the use of any tools or having to recalibrate.

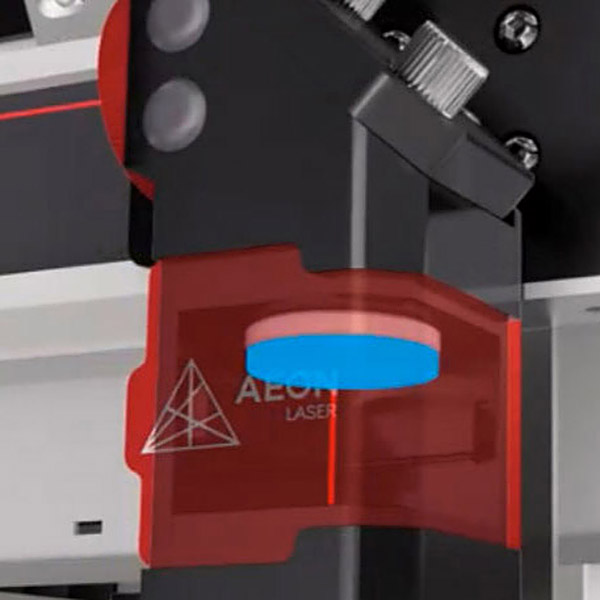

Lens Cartridges

The lens cartridges on all Redline models are now magnetic and the focal lens itself is press fit with a silicone washer, for easy access.

INTUITIVE & PROACTIVE

LCD Display

The most recent revision to the NOVA Keypad now makes its way to the MIRA Redline Series, which brings commonly used functions right to the surface, for reduced setup times and overall ease of use. You can even monitor water temperature, amperage (mA), air pressure (psi), and the temperature of your optics right from the vibrant 5″ LCD display, for the ultimate user experience.

Smart Monitoring

All optics are now fitted with thermal sensors to record and report temperature readings to the keypad, thus eliminating the likelihood of unexpected failures. This proactive approach not only saves you from costly mistakes and downtime, it also reduces the need for frequent unwarranted cleaning. To top it off, the controller now records these readings along with ambient temperature, laser tube runtime and machine parameters, to serve as a diagnostic log in the event troubleshooting is needed.

SAFE-GUARDED

Optics

To further reduce the need for maintenance, all optics are now fully removed from the work area, taking the Clean Pack Design to its highest potential.

Laser Head

With the laser head sealed to where no dust or debris can enter, all that remains are a series of cost effective windows, which are far easier to maintain and replace if needed.

REDLINE First Impressions

Want to see them?

FAQ’S

Your question not here? Get in touch, we are always happy to help.

Where can I learn more about the REDLINE Series

See the NEW Redline product pages for pricing, specs, addons, and more details:

MIRA S Redline

MIRA Pro S Redline

NOVA S Redline

Super NOVA S Redline

Where can I see the REDLINE Series

Please Contact us is you would like to schedule a visit to see them in person at our warehouse or even “in the wild” at one of our customer’s sites.

When will REDLINE series be available for order?

Most REDLINE models are available in NZ ex-stock NOW!

What is the difference between a Glass Tube and RF Metal Tube?

CO2 lasers are commonly used for various applications like cutting, engraving, and marking. The type of laser tube used in these devices plays a crucial role in their performance, lifespan, and maintenance requirements. Here’s a breakdown of the differences between glass tubes & RF metal tubes in CO2 lasers:

Glass Tube

- Material: These are typically made from sealed glass containing a CO2 gas mixture. The electrodes are often copper.

- Excitation Method: Glass tubes use DC (Direct Current) excitation. The electrical discharge happens directly through the gas mixture to create the laser beam.

- Cooling: Requires external water cooling systems. Proper cooling is essential to avoid overheating and extend tube life.

- Cost: Relatively inexpensive and widely used in professional, prosumer and hobbyist CO2 lasers alike.

- Applications: Suitable for a wide range of uses from large production machines to small desktop models.

RF Metal Tube

- Material: Made from metal, these tubes are designed to withstand higher power and are more robust.

- Excitation Method: RF (Radio Frequency) excitation, where an external RF generator powers the tube without direct contact with the gas mixture.

- Cooling: Can often be air-cooled due to the efficient RF excitation, though some high-power tubes require water cooling.

- Cost: Considerably more expensive than glass tubes but offer greater durability and longer life.

- Applications: Ideal for industrial settings and high-power applications due to their longer lifespan and robustness.

Key factors to consider when comparing RF Laser Tubes and DC Glass Laser Tubes

1. Beam Profile The beam profile plays a significant role in cutting quality. You ideally want a larger beam diameter going into the lens to cut well. An RF tube uses a beam expander (typically 2.5x) but beam expanders don’t allow for enough size increase to match a glass laser tube. Glass laser tubes have an advantage here.

2. Pulses vs Continuous Power 2. RF laser tubes operate in pulses, similar to a light switch flicking on and off thousands of times a second. A glass laser tube stays on continuously, providing uninterrupted power. This leads to smoother cutting, as there’s no delay or pause between pulses.

Will my existing rotary work with the new REDLINE machines?

Yes, the REDLINE models are compatible with all of the rotary attachments we offer.

Will a 40oz Stanley Dupe Tumbler fit in a REDLINE laser machine for engraving or customisation?

Yes, it will fit. We tested a 40oz Stanley Dupe Tumbler in a MIRA5 S Redline laser using our advanced roller rotary at the correct focal height for a 2.5-inch lens. The tumbler fits comfortably, leaving room to spare.

For reference, the Z Axis Travel Height on the MIRA5 S and MIRA7 S is 140mm, MIRA9 S is 150mm. All NOVA S and Super NOVA S models are 200mm.

Did the work area of the REDLINE models get larger or are they all the same size beds as the original models?

The MIRA7 S is the only one that got a larger work area, going from 450mm to 500mm on the Y axis.

Can the original Aeon models be upgraded to any of the new features on the AEON REDLINE series machine?

Unfortunately, no. The Redline models have been redesigned from the ground up.

Can I trade my existing machine in on a REDLINE machine?

Speak to us! We often get requests for quality used macines from budget constrained customers.

Are you interested in the Redline series lasers?

Chat to one of our friendly, NZ based team today.